Finishing

Finishing

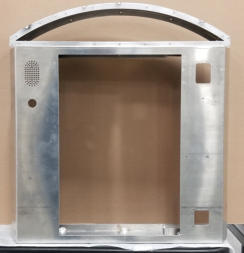

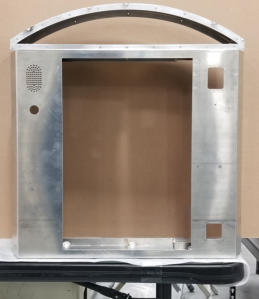

Finishing is perhaps one of the most important steps in the process. Often over looked, finishing is the part that can make your product look just so so or truly the product you expect your customer to see. This is where the smooth surface, straight edges, no burrs no pits happens. We consider this so important, we have dedicated an entire enclosed area to the process. Our crew work as Craftsmen to insure your product looks the best it can be. To this end, we employ a variety of methods and equipment to provide this service. Much of the finishing is done by hand, deburring, grinding, sanding, and honing to a smooth and true surface, meeting or exceeding your expectations. We also have equipment to assist us in the finishing process like the Amada Notcher. The Amada CSW-250 is one of the most versatile pieces of cutting equipment in our inventory. Known as a Notcher or Corner Shear, this 10 ton unit has the ability to do Notching and Coping, and to cut a radius in mild steel up to .125”. With this unit we can reduce deburring and finishing time while providing cleaner edges, cuts, and notching.

© Ginko Metal Works LLC

Made with Xara

Finishing

© Ginko Metal Works LLC

Finishing

Finishing

Finishing is perhaps one of the most important steps in the process. Often over looked, finishing is the part that can make your product look just so so or truly the product you expect your customer to see. This is where the smooth surface, straight edges, no burrs no pits happens. We consider this so important, we have dedicated an entire enclosed area to the process. Our crew work as Craftsmen to insure your product looks the best it can be. To this end, we employ a variety of methods and equipment to provide this service. Much of the finishing is done by hand, deburring, grinding, sanding, and honing to a smooth and true surface, meeting or exceeding your expectations. We also have equipment to assist us in the finishing process like the Amada Notcher. The Amada CSW-250 is one of the most versatile pieces of cutting equipment in our inventory. Known as a Notcher or Corner Shear, this 10 ton unit has the ability to do Notching and Coping, and to cut a radius in mild steel up to .125”. With this unit we can reduce deburring and finishing time while providing cleaner edges, cuts, and notching.

Finishing

Laser Cutting

Machining

Punching

Welding

Finishing

Finishing is perhaps one of the most important steps in the process. Often over looked, finishing is the part that can make your product look just so so or truly the product you expect your customer to see. This is where the smooth surface, straight edges, no burrs no pits happens. We consider this so important, we have dedicated an entire enclosed area to the process. Our crew work as Craftsmen to insure your product looks the best it can be. To this end, we employ a variety of methods and equipment to provide this service. Much of the finishing is done by hand, deburring, grinding, sanding, and honing to a smooth and true surface, meeting or exceeding your expectations. We also have equipment to assist us in the finishing process like the Amada Notcher. The Amada CSW-250 is one of the most versatile pieces of cutting equipment in our inventory. Known as a Notcher or Corner Shear, this 10 ton unit has the ability to do Notching and Coping, and to cut a radius in mild steel up to .125”. With this unit we can reduce deburring and finishing time while providing cleaner edges, cuts, and notching.

© Ginko Metal Works LLC

Made with Xara