Punching

Punching

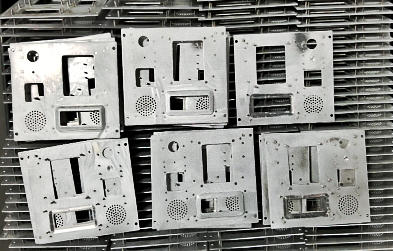

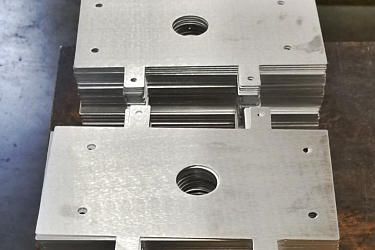

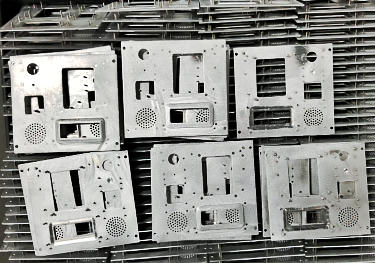

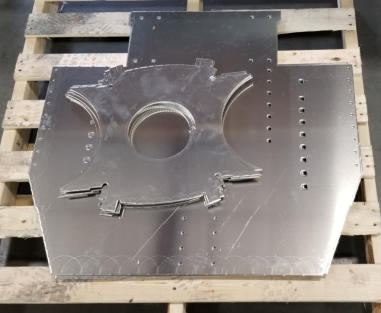

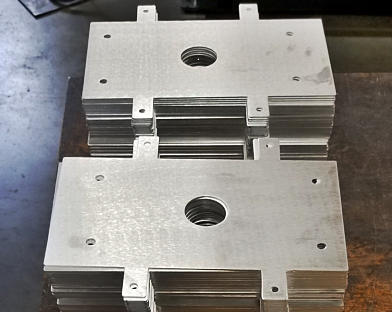

We at Ginko Metal Works LLC take our Punch Presses with a bit of pride. After all the Punch Press was the first piece of equipment that helped launch Ginko Metal Works so many years ago. The Punch Press with the proper tooling is the ideal piece of equipment to cut thousands of parts with multiple hole and cutouts. They can also be setup to run short runs quickly through the CNC Controller. The Punch Press is often the most cost effective process for a variety of parts. We now have four Amada CNC Turret Punch Presses. Each Punch Press is rated at 30 tons, with an auto indexing turret, and a servo positioning table. Beyond that each unit has its own table size, speed, turret size, and other special features like Auto Loading. Even with the quality and capabilities of the Punches, they’re only as good as their tooling and operators. Over time we have built up an impressive inventory of tooling, standard, custom and in-house designed and produced. Our operators are experienced in producing the best quality Punch Press Parts. Between the Punches, Lasers and Notcher at Ginko Metal Works you can be assured that we will have the right equipment to handle your application accurately and efficiently.

© Ginko Metal Works LLC

Made with Xara

© Ginko Metal Works LLC

Punching

Punching

We at Ginko Metal Works LLC take our Punch Presses with a bit of pride. After all the Punch Press was the first piece of equipment that helped launch Ginko Metal Works so many years ago. The Punch Press with the proper tooling is the ideal piece of equipment to cut thousands of parts with multiple hole and cutouts. They can also be setup to run short runs quickly through the CNC Controller. The Punch Press is often the most cost effective process for a variety of parts. We now have four Amada CNC Turret Punch Presses. Each Punch Press is rated at 30 tons, with an auto indexing turret, and a servo positioning table. Beyond that each unit has its own table size, speed, turret size, and other special features like Auto Loading. Even with the quality and capabilities of the Punches, they’re only as good as their tooling and operators. Over time we have built up an impressive inventory of tooling, standard, custom and in-house designed and produced. Our operators are experienced in producing the best quality Punch Press Parts. Between the Punches, Lasers and Notcher at Ginko Metal Works you can be assured that we will have the right equipment to handle your application accurately and efficiently.

Punching

Laser Cutting

Machining

Punching

Welding

Punching

We at Ginko Metal Works LLC take our Punch Presses with a bit of pride. After all the Punch Press was the first piece of equipment that helped launch Ginko Metal Works so many years ago. The Punch Press with the proper tooling is the ideal piece of equipment to cut thousands of parts with multiple hole and cutouts. They can also be setup to run short runs quickly through the CNC Controller. The Punch Press is often the most cost effective process for a variety of parts. We now have four Amada CNC Turret Punch Presses. Each Punch Press is rated at 30 tons, with an auto indexing turret, and a servo positioning table. Beyond that each unit has its own table size, speed, turret size, and other special features like Auto Loading. Even with the quality and capabilities of the Punches, they’re only as good as their tooling and operators. Over time we have built up an impressive inventory of tooling, standard, custom and in-house designed and produced. Our operators are experienced in producing the best quality Punch Press Parts. Between the Punches, Lasers and Notcher at Ginko Metal Works you can be assured that we will have the right equipment to handle your application accurately and efficiently.

© Ginko Metal Works LLC

Made with Xara