© Ginko Metal Works LLC

Made with Xara

This

Page

Shows

the

many

Capabilities

of

Ginko

Metal

Works.

For

more

detailed

explanation of the Capabilities and Services click on the Panel of Interest.

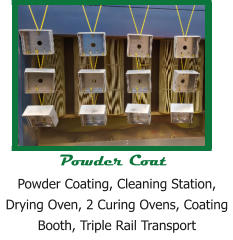

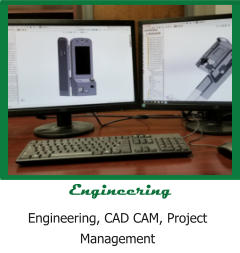

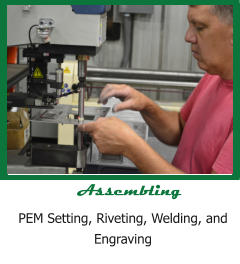

Capabilities