Laser Cutting

Laser Cutting

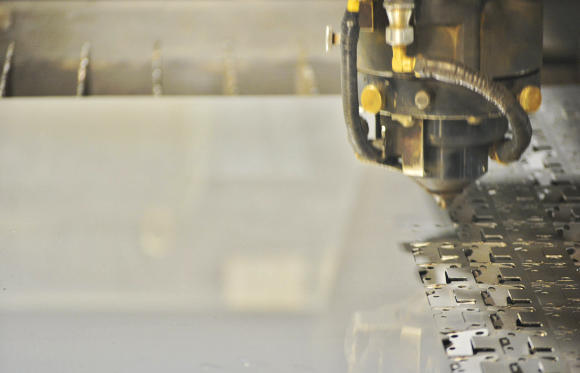

The laser has revolutionized the metal working industry. From guiding to locating to cutting, we depend on the laser in the modern metal working shop. At Ginko Metal Works LLC we use all types of lasers for different purposes, but our laser cutting is where we truly shine. We now have four laser cutters allowing us to optimize our cutting process, and to match the job to the best process. With the diversity of our lasers, you can be assured your job will run on the optimum equipment for your project. The each laser has their own specialties in cutting. Power, Speed, Maneuverability, Accuracy, Part Size, Thickness, and Cost to Operate are unique capabilities of our lasers. Our most powerful Flying Optics Laser is capable of cutting 1” cold roll steel plate. We have two fixed head laser cutters that require less power and can handle larger projects. They can handle very large parts by re-indexing the part on the servo-positioned table, and our latest addition is a Laser Cutter that is designed to cut the most challenging parts quick and easily. Even though lasers are typically used for Iron, Steel, and Aluminum, they can cut most materials including metallic and non-Metallic materials. Accuracy and repeatability are the trademark of our lasers. They have the ability to cut 1” cold roll steel, while on the other end, we can cut sheet Aluminum as thin as .010” while maintaining our high tolerances.

Our

two

Amada

667-II

Lasers

are

2400

Watt

Fanuc

Lasers

and

CNC

Controllers.

They

have

movable

tables

with

re-indexing,

effectively

doubling

the

working

area

providing

us

the

ability

to

cut

even

the

largest

over

sized

projects.

Our

Amada

Laser

FO-3015

has

a

Fanuc

4000

Watt

Flying

Optics

Laser

and

CNC

Controller

and

with

the

ability

to

cut

up

to

1”

cold

roll

steel

plate

with

an

accuracy

of

.0002”.

Its

fixed

table

offers

a

working

area

of

121”

x

61”

and

the

cast

iron

frame

has

a

workload

of

2000

pounds.

Even

with

all

that

power,

it

can

still

cut

this

.125”

Blue

Lexan.

Our

newest

laser

the

Amada

FO

MII

3015

NT

with

flying

optics

is

also

a

4000

Watt

laser,

but

due

to

improvements

in

optics

and

the

laser

itself,

we

can

now

cut

up

to

1”

cold

roll

steel

reliably.

The

fixed

table

offers

a

working

area

of

121”

x

61”

and

a

workload

of

2000

lbs,

makes this our next generation of Laser cutters.

© Ginko Metal Works LLC

Made with Xara

© Ginko Metal Works LLC

Laser Cutting

The laser has revolutionized the metal working industry. From guiding to locating to cutting, we depend on the laser in the modern metal working shop. At Ginko Metal Works LLC we use all types of lasers for different purposes, but our laser cutting is where we truly shine. We now have four laser cutters allowing us to optimize our cutting process, and to match the job to the best process. With the diversity of our lasers, you can be assured your job will run on the optimum equipment for your project. The each laser has their own specialties in cutting. Power, Speed, Maneuverability, Accuracy, Part Size, Thickness, and Cost to Operate are unique capabilities of our lasers. Our most powerful Flying Optics Laser is capable of cutting 1” cold roll steel plate. We have two fixed head laser cutters that require less power and can handle larger projects. They can handle very large parts by re-indexing the part on the servo-positioned table, and our latest addition is a Laser Cutter that is designed to cut the most challenging parts quick and easily. Even though lasers are typically used for Iron, Steel, and Aluminum, they can cut most materials including metallic and non-Metallic materials. Accuracy and repeatability are the trademark of our lasers. They have the ability to cut 1” cold roll steel, while on the other end, we can cut sheet Aluminum as thin as .010” while maintaining our high tolerances.

Our

two

Amada

667-II

Lasers

are

2400

Watt

Fanuc

Lasers

and

CNC

Controllers.

They

have

movable

tables

with

re-indexing,

effectively

doubling

the

working

area

providing

us

the

ability

to

cut

even

the

largest

over

sized

projects.

Our

Amada

Laser

FO-3015

has

a

Fanuc

4000

Watt

Flying

Optics

Laser

and

CNC

Controller

and

with

the

ability

to

cut

up

to

1”

cold

roll

steel

plate

with

an

accuracy

of

.0002”.

Its

fixed

table

offers

a

working

area

of

121”

x

61”

and

the

cast

iron

frame

has

a

workload

of

2000

pounds.

Even

with

all

that

power,

it

can

still

cut

this

.125”

Blue

Lexan.

Our

newest

laser

the

Amada

FO

MII

3015

NT

with

flying

optics

is

also

a

4000

Watt

laser,

but

due

to

improvements

in

optics

and

the

laser

itself,

we

can

now

cut

up

to

1”

cold

roll

steel

reliably.

The

fixed

table

offers

a

working

area

of

121”

x

61”

and

a

workload

of

2000

lbs,

makes

this

our

next

generation

of

Laser

cutters.

Laser Cutting

Machining

Punching

Welding

Laser Cutting

Laser Cutting

The laser has revolutionized the metal working industry. From guiding to locating to cutting, we depend on the laser in the modern metal working shop. At Ginko Metal Works LLC we use all types of lasers for different purposes, but our laser cutting is where we truly shine. We now have four laser cutters allowing us to optimize our cutting process, and to match the job to the best process. With the diversity of our lasers, you can be assured your job will run on the optimum equipment for your project. The each laser has their own specialties in cutting. Power, Speed, Maneuverability, Accuracy, Part Size, Thickness, and Cost to Operate are unique capabilities of our lasers. Our most powerful Flying Optics Laser is capable of cutting 1” cold roll steel plate. We have two fixed head laser cutters that require less power and can handle larger projects. They can handle very large parts by re-indexing the part on the servo-positioned table, and our latest addition is a Laser Cutter that is designed to cut the most challenging parts quick and easily. Even though lasers are typically used for Iron, Steel, and Aluminum, they can cut most materials including metallic and non- Metallic materials. Accuracy and repeatability are the trademark of our lasers. They have the ability to cut 1” cold roll steel, while on the other end, we can cut sheet Aluminum as thin as .010” while maintaining our high tolerances.

Our

two

Amada

667-II

Lasers

are

2400

Watt

Fanuc

Lasers

and

CNC

Controllers.

They

have

movable

tables

with

re-indexing,

effectively

doubling

the

working

area

providing

us

the

ability

to

cut

even

the

largest

over

sized

projects.

Our

Amada

Laser

FO-3015

has

a

Fanuc

4000

Watt

Flying

Optics

Laser

and

CNC

Controller

and

with

the

ability

to

cut

up

to

1”

cold

roll

steel

plate

with

an

accuracy

of

.0002”.

Its

fixed

table

offers

a

working

area

of

121”

x

61”

and

the

cast

iron

frame

has

a

workload

of

2000

pounds.

Even

with

all

that

power,

it

can

still

cut

this

.125”

Blue

Lexan.

Our

newest

laser

the

Amada

FO

MII

3015

NT

with

flying

optics

is

also

a

4000

Watt

laser,

but

due

to

improvements

in

optics

and

the

laser

itself,

we

can

now

cut

up

to

1”

cold

roll

steel

reliably.

The

fixed

table

offers

a

working

area

of

121”

x

61”

and

a

workload of 2000 lbs, makes this our next generation of Laser cutters.

© Ginko Metal Works LLC

Made with Xara